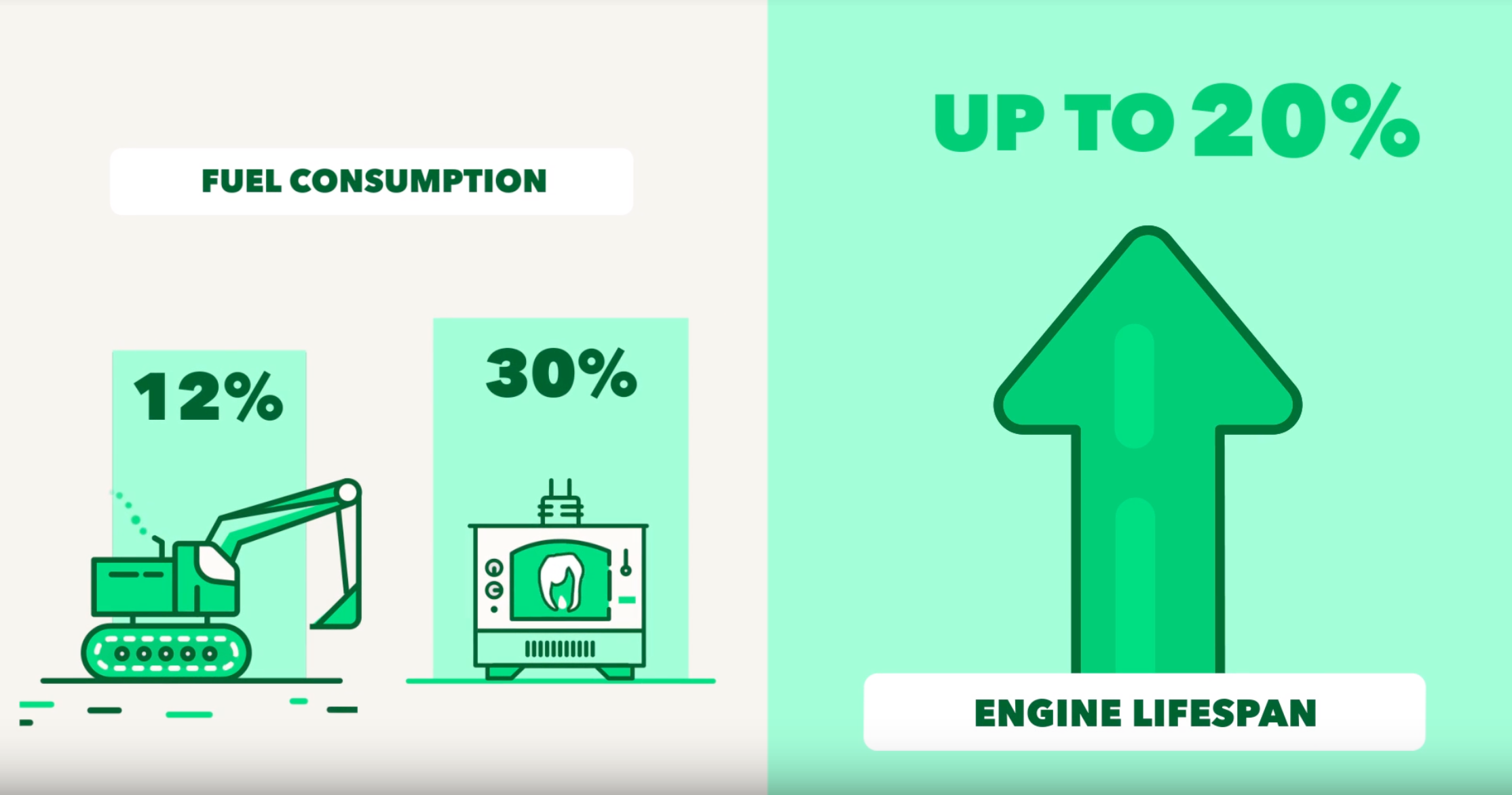

The savings can be massive. In addition to reducing fuel costs, the Rentar Fuel Catalyst can also reduce wear and tear on the engines and boilers to which it’s attached. How? The fuel that isn’t burned off typically builds up inside an engine as soot or carbon buildup. Trapped in the crankcase, it can contaminate the oil and eventually lead to breakdowns. Oil analysis tests have proved that by using the Rentar Fuel Catalyst, fuel soot levels are substantially reduced. For boilers, there is less buildup of carbon on the internal surfaces of the boiler itself causing constant maintenance and inefficient operation.

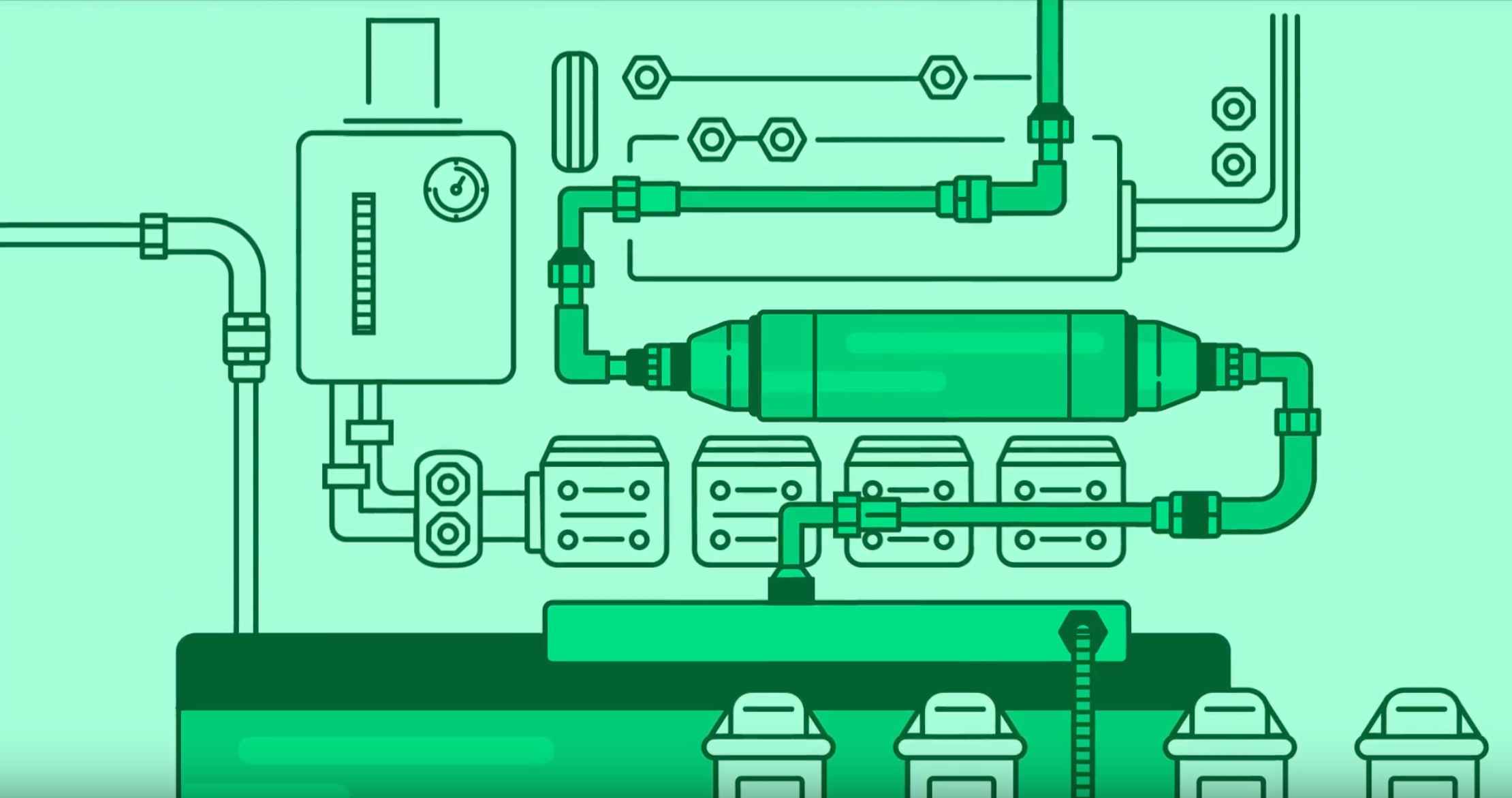

When fuel passes through the Rentar Fuel Catalyst’s patented combination of metallic and rare earth elements, a reaction occurs just prior to combustion that separates the clustered molecules so more are exposed to oxygen. As the combustion process is completed, far fewer fuel molecules are wasted and spewed from the engine as exhaust. In addition the other most important reaction is the change in the proportion of saturated straight chain aliphatic paraffin’s to unsaturated ring compound aromatics which lead to dehydrogenation of the saturated hydrocarbon chain resulting in the release of a small quantity of hydrogen gas.